https://sliced2go.com/wp-content/uploads/2023/03/308i.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-03-19 21:25:432026-02-22 14:50:11How Automatic Slicers for Sushi Can Help Meet Your Culinary Needs

https://sliced2go.com/wp-content/uploads/2023/03/308i.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-03-19 21:25:432026-02-22 14:50:11How Automatic Slicers for Sushi Can Help Meet Your Culinary NeedsCommercial Deli Meat Slicer Maintenance Tips

Every commercial kitchen needs a safe and well-functioning deli meat slicer. This not only ensures the efficient operation of the establishment but also guarantees the customer’s safety. However, these machines can also pose a safety issue if not properly cared for and maintained. This article provides comprehensive details on automatic commercial deli meat slicers, their maintenance, and why the regular upkeep of these machines is essential. We also delve into the various routine customs that can maintain the slicer’s efficiency and longevity. Let’s embark on this journey of discovery on how to sustain your valuable investment.

Understanding Automatic Commercial Deli Meat Slicers

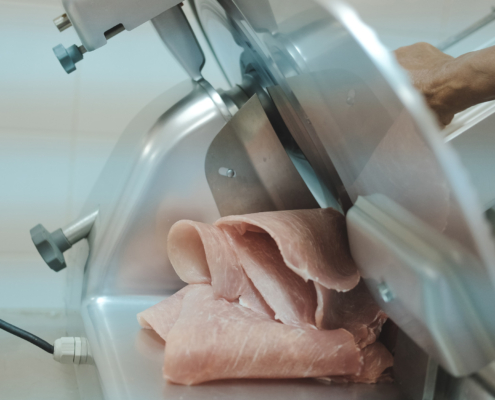

An automatic commercial deli meat slicer, also known as a food slicer, is a vital tool in most deli kitchens or food prep stations. Designed to precisely cut meat into varying thicknesses, ranging from deli-style paper-thin slices to thicker chops, these commercial meat slicers offer a level of uniformity unachievable by manual cutting.

As much as automatic deli slicers revolutionize the kitchen, they are also complex gadgets with a design that makes cleaning somewhat intricate. However, keeping these slicers clean can significantly prolong their lifespan and keep the quality of the cut meat consistent. Understanding the working of these commercial meat slicers is essential to adequately maintaining them.

After-Use Cleaning

After every use of the commercial deli meat slicer, it should be thoroughly cleaned to remove food residue. This involves washing the parts of the meat slicer that come into contact with food, such as the blade, carriage, food pusher, and slicer table. Wipe them down with a gentle detergent and warm water, rinse, and then thoroughly dry.

Switching Off and Unplugging the Machine

For safety reasons and to prevent damage to the machine, before cleaning, always ensure to switch off and unplug your commercial meat slicer. Handling a plugged-in slicer when cleaning poses a serious injury risk and also exposes the slicer to potential electric and water damage.

Blade Cleaning

Blade cleaning cannot be underestimated in a commercial deli meat slicer. With a blade that is keenly sharp and regularly meeting fatty meat, maintaining it clean and sharp becomes top priority. Recommended is use of a scrub pad designed for slicer blades for better results and to mitigate risk of injuries. Lubricating the sharpening stone and sharpening the blade at least once every day, will guarantee you perfectly sliced meat at an affordable price continuously.

Preventive Measures

Regular maintenance of commercial meat slicers should be accompanied by preventive measures to prolong machine durability. Users should regularly inspect the slicer for possible wear and tear, lubricate the sliding parts, check and adjust the slicer’s thickness setting, and regularly check the sharpness of the blade. Create a convenient maintenance schedule to ensure these tasks are done consistently for a lasting slicer.

Lubrication of the Slicer Parts

Lubrication is a significant component of a commercial deli meat slicer’s preventive maintenance. Regular lubricating the sliding or movable parts of the slicer reduces friction, thus reducing the rate of wear and tear. Verify your slicer’s manual to apply the recommended type of lubricant on the correct slicer parts.

Checking for Damages

A regular inspection of the mechanical components of your automatic slicer strategically aids to detect any problems before they escalate into significant damages. From loose parts to unusual sounds, any malfunction not handled immediately can compromise the efficiency of the slicer.

Deep Cleaning Schedule

While daily cleaning focuses on parts that come directly into contact with food, deep cleaning even targets hidden parts where food may have accumulated over time. It may be necessary to disassemble the food slicer for this type of cleaning. Always refer to the manufacturer’s manual to ensure that the slicer is disassembled and reassembled correctly.

Get Modern Slicers That Last With Sliced2Go

If you are looking for a commercial meat slicer built with durability and effective performance in mind, look no further than Sliced2Go. We offer a wide range of commercial deli slicers, such as the PX3, X3, and beyond. Our slicers are suitable for different food prep needs, designed to withstand regular use, yet remain efficient.

Keep your deli customers impressed with precisely cut meat slices each time, every time.

Share This Post

More Like This

https://sliced2go.com/wp-content/uploads/2023/03/308i.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-03-19 21:25:432026-02-22 14:50:11How Automatic Slicers for Sushi Can Help Meet Your Culinary Needs

https://sliced2go.com/wp-content/uploads/2023/03/308i.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-03-19 21:25:432026-02-22 14:50:11How Automatic Slicers for Sushi Can Help Meet Your Culinary Needs

10 Creative Meat Slicer Recipes

Meat Slicers

Commercial Deli Meat Slicer Maintenance Tips

Meat Slicers

Best Practices for Automatic Meat Slicer Use

Meat Slicers

How an Automatic Meat Slicer Enhances Charcuterie Boards

Meat Slicers https://sliced2go.com/wp-content/uploads/2024/01/Exploring-the-Dos-and-Donts-of-Grab-‘n-Go-Deli.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-01-11 17:41:592024-03-05 23:25:48Exploring the Do’s and Don’ts of Grab ‘n Go Deli

https://sliced2go.com/wp-content/uploads/2024/01/Exploring-the-Dos-and-Donts-of-Grab-‘n-Go-Deli.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-01-11 17:41:592024-03-05 23:25:48Exploring the Do’s and Don’ts of Grab ‘n Go Deli

Exploring Automated Meat Slicers

Automation, Meat Slicers

How to Enhance Charcuterie Board Meats and Cheeses

Meat SlicersLocation

Get In Touch

Phone

773-919-2153

Email

sales@sliced2go.com

Address

2521 Technology Drive, 203, Elgin, Illinois, 60124

Our Slicers

The PX3: A Comprehensive Slicing and Packaging Solution

The X3: A High Volume Slicer and Packager for Extreme Demands

The RX3: A Scaled-Down Slicer With Total Capabilities

The 308: A Starter Slicer That’s Basic and Budget Friendly

The PX3 MAP: A Modified PX3 With Gassing and Map Packing