https://sliced2go.com/wp-content/uploads/2023/03/308i.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-03-19 21:25:432026-02-01 14:47:25How Automatic Slicers for Sushi Can Help Meet Your Culinary Needs

https://sliced2go.com/wp-content/uploads/2023/03/308i.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-03-19 21:25:432026-02-01 14:47:25How Automatic Slicers for Sushi Can Help Meet Your Culinary NeedsBest Practices for Automatic Meat Slicer Use

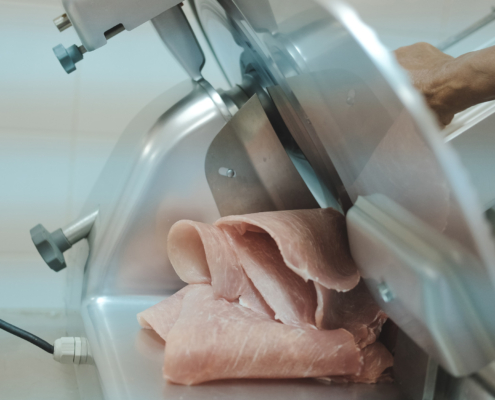

The automatic meat slicer has become an indispensable tool for commercial kitchens, restaurants, and home enthusiasts alike. A versatile device, the meat slicer can significantly ease the workload, maximizing efficiency while ensuring a consistently high-quality product. This article takes you through all details associated with the use of automatic meat slicers, from understanding the basic operability and adjusting it based on your requirements, to maintaining sanitation and ensuring personal safety. Additionally, we discuss the importance of complying with health and safety regulations and maintaining your appliance for longevity. We promise you tips and tricks along the way that will make your meat slicing experience smoother and safer.

Understanding Basic Automatic Meat Slicer Operability

The basic operation of a commercial meat slicer is something that every user working in a commercial kitchen needs to fully comprehend. Understanding how the slicer works forms the basis of its efficient and safe use. First and foremost, it’s important to acknowledge that a meat slicer is not a toy; it’s a powerful tool that can deliver professional-grade sliced meat if handled correctly.

Checking the Power Source and Slicing Speed

In using a commercial meat slicer, an appropriate power source is crucial. In addition to this, it is crucial to consider the slicer’s speed. Just as a car performs better, lasts longer, and becomes safer with regular maintenance, your meat slicer will perform optimally when it’s used in the right electrical environment and maintained to optimum condition. This dictates its performance in speeding up the slicing work while delivering consistent slice thickness.

Studying the User Manual for Operation Guidelines

Another critical aspect of learning the basic operability of commercial meat slicers is immersing oneself in the User Manual importance. Even the most experienced users require this guideline, not only to understand the operating principles of the slicer but also to gain insights into the do’s and don’ts while in operation. Knowledge about how to use safety guard accessories, instructional tips on adjusting the carriage tray, and advice on effective procedures in case of a malfunction are valuable information provided in the manual.

Setting Up the Slicer for Desired Meat Cutting Thickness

Adjusting the meat thickness is undoubtedly one of the most critical tasks in meat slicer use. Different dishes require different thicknesses; hence knowing how to adjust the slicer to achieve this helps in delivering the desired results. This setting process can be daunting, especially to novices, but with time and practice, one can navigate it with ease. Remember to always secure the meat properly on the carriage tray while adjusting the thickness level.

Get Slicers With Easy Set Up With Sliced2Go

To enhance usability, selecting easy-to-set-up slicers, such as those from Sliced2Go, is recommended. These heavy-dutyslicers are not only easy to use but also provide comprehensive user-friendly manuals that guide users on each step. Their high-quality safety guards further enhance your meat slicing and experience.

Food Safety and Sanitation for Meat Slicer Use

Food safety and sanitation cannot be overemphasized during meat slicer use. Any lapse in these areas can lead to contamination, which can jeopardize the health of consumers. Thus, it’s crucial to ensure cleanliness and sanitation are maintained at all times.

Importance of Cleanliness in Handling Raw and Cooked Meat

Handling raw and cooked meat with cleanliness is paramount to prevent cross-contamination. For instance, all the tools involved (including the slicers themselves) should be sterilized before and after use. Following the listed guidelines in the User Manual about cleaning and maintaining hygiene during meat slicer use is vital.

Maintaining Proper Sanitation to Meet Health and Safety Regulations

The importance of maintaining sanitation standards in a commercial kitchen cannot be overstated. It’s not just about the health of the consumers; it’s also about adhering to the set health and safety guidelines by relevant authorities. Non-compliance can result in penalties or even closure of the business. Therefore, procedures such as regular cleaning and disinfection of the slicer, using protective gloves, masks, and aprons should always be adhered to.

Effective Waste Management for Remains From the Slicing Process

During the slicing process, there’s bound to be waste residue, including excess meat, fat, and bone fragments. Effective waste management ensures this is disposed of properly without posing hazards. Waste disposal containers should be adequately sealed and situated in a place away from the slicing area and often emptied. Planning for waste disposal is as important as the slicing process itself.

Ensuring Personal Safety and Slicer Maintenance

One fundamental aspect of operating a commercial meat slicer is ensuring personal safety. This process not only involves adhering to safety measures regarding blade handling but also consistent slicer maintenance.

Adherence to Meat Slicer Safety Measures on Blade Safety

Proper meat slicer use practices always highlight the importance of blade safety. The blade of any meat slicer, let alone a commercial meat slicer, is sharp enough to cause severe injuries. Therefore, employees must adhere to stringent safety protocols.

- Ensuring the slicer is turned off before cleaning, adjusting the slice thickness, or any other modification is crucial.

- The use of safety guards wherever applicable limits the operator’s direct contact with the blade, thus reducing the risk of cutting accidents.

- Specialized tools should be used for blade removal or installation to avoid direct handling.

These practices play a key role in the safe operation of meat slicers in a commercial kitchen, ensuring both the operator’s safety and the slicer’s longevity.

Importance of Personal Protection Equipment While Operating the Slicer

Personal Protection Equipment (PPE) is paramount when it comes to meat slicer use in commercial kitchens. The use of cut-resistant gloves is widespread to guard against accidents. These gloves provide a protective layer between the operator’s hands and the slicer blade, reducing potential injuries caused by accidental contact with the blade.

Additionally, using slip-resistant shoes can prevent unwanted accidents that could be triggered by accidental slips, especially in busy commercial kitchens. Lastly, operators in commercial kitchens should wear fitted clothing and restrain hair or any loose-fitting accessories to prevent entanglement with the slicer’s moving parts.

Routine Blade Sharpening and Slicer Maintenance (Includes Cleaning)

The maintenance, including the routine cleaning and blade sharpening of any commercial meat slicer, is crucial to ensure longevity and prevent cross-contamination of sliced meat. A clean, well-maintained slicer minimizes the risk of bacterial spread and ensures consistent slice thickness.

- On every slicer cleaning operation, ensure the slicer is unplugged from the power source.

- Debris should be removed from the blade, carriage tray, safety guard, and other parts of the slicer using a dull scraper or a brush.

- After the debris is removed, sanitize the slicer parts, including blade, using a food-grade sanitizer. Never immerse the slicer in water.

- Regular blade sharpening improves the slicer’s performance, helps maintain uniform slice thickness, and prolongs the blade’s service life. Blade sharpeners are often included for easy duty slicers.

By maintaining the commercial meat slicer’s cleanliness and sharpening the blades when needed, businesses can provide fresh, evenly sliced meat while maintaining high food safety standards.

Legal and Health Compliance in Meat Slicing

Complying with legal and health standards is non-negotiable in any commercial kitchen. Establishments must adhere to both local and federal safety regulations to operate lawfully. They are also responsible for the assurance that their meat slicers meet all manufacturing and operational standards.

Adhering to Regional and Federal Health and Safety Regulations

Commercial kitchens need to ensure their meat slicers’ functioning complies with regional and federal safety guidelines to ensure optimal food safety. Enforcing hygiene protocols, including regular slicer cleaning and maintenance, plays a significant role in satisfying these regulations.

Kitchen staff should be educated and trained in following the established safety protocol. Frequent evaluation of these processes through audits or inspections helps to verify that the commercial kitchen is dedicated to the highest levels of safety and sanitation.

Ensuring the Slicer Meets All Manufacturing and Operation Standards

Before deploying for meat slicer use, establishments have an obligation to ensure that their commercial meat slicers are up to par with both manufacturing and operation standards. Features such as safety guards, easy-to-clean parts, and adjustable slice thickness features are crucial. Also, an alarm system to indicate improper assembly can avoid potential hazards.

Certification from recognized organizations like NSF International not only verifies that your slicer meets health standards but also builds customers’ confidence in your sanitary food preparation practices.

Get Your Next Slicer With Sliced2Go

Choosing a heavy-duty and reliable commercial meat slicer can streamline operations in your commercial kitchen. With Sliced2Go, you can acquire slicers aligned with health and safety guidelines. Each slicer we sell undergoes rigorous tests to ensure they meet the set manufacturing and operational standards.

Equip your commercial kitchen with Sliced2Go! Our range of high-quality, safety-compliant meat slicers are designed to cater to the most demanding of slice thickness requirements. They come with easy set-up features and adhere to safety and sanitary standards fit for commercial kitchen use. Contact us to learn more.

Share This Post

More Like This

https://sliced2go.com/wp-content/uploads/2023/03/308i.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-03-19 21:25:432026-02-01 14:47:25How Automatic Slicers for Sushi Can Help Meet Your Culinary Needs

https://sliced2go.com/wp-content/uploads/2023/03/308i.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-03-19 21:25:432026-02-01 14:47:25How Automatic Slicers for Sushi Can Help Meet Your Culinary Needs

10 Creative Meat Slicer Recipes

Meat Slicers

Commercial Deli Meat Slicer Maintenance Tips

Meat Slicers

Revolutionizing Sushi Preparation With Automated Sushi Slicers

Automation

Why Your Sushi Business Needs to Invest In an Automatic Sushi Slicer

Automation

Best Practices for Automatic Meat Slicer Use

Meat Slicers

How an Automatic Meat Slicer Enhances Charcuterie Boards

Meat Slicers https://sliced2go.com/wp-content/uploads/2024/01/Exploring-the-Dos-and-Donts-of-Grab-‘n-Go-Deli.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-01-11 17:41:592024-03-05 23:25:48Exploring the Do’s and Don’ts of Grab ‘n Go Deli

https://sliced2go.com/wp-content/uploads/2024/01/Exploring-the-Dos-and-Donts-of-Grab-‘n-Go-Deli.jpg

1250

2000

Abstrakt Marketing

/wp-content/uploads/2023/05/Sliced2Go-Logo-full-coloor.png

Abstrakt Marketing2024-01-11 17:41:592024-03-05 23:25:48Exploring the Do’s and Don’ts of Grab ‘n Go Deli

Exploring Automated Meat Slicers

Automation, Meat SlicersLocation

Get In Touch

Phone

773-919-2153

Email

sales@sliced2go.com

Address

2521 Technology Drive, 203, Elgin, Illinois, 60124

Our Slicers

The PX3: A Comprehensive Slicing and Packaging Solution

The X3: A High Volume Slicer and Packager for Extreme Demands

The RX3: A Scaled-Down Slicer With Total Capabilities

The 308: A Starter Slicer That’s Basic and Budget Friendly

The PX3 MAP: A Modified PX3 With Gassing and Map Packing